Not to be confused with meteorology, meteorology is the science that measures. It creates a shared understanding of units that is essential for linking human activities. The French Revolution was the catalyst for modern metrology. A length standard derived from a natural resource was used to standardize French units. In 1795, the decimal-based system of metric measurements was created. The decimal based metric system also helped establish standards for other types measurements.

3D Metrology

It is important to understand how 3D metrology can be applied to other fields. The field is divided into three main overlapping activities.

Legal Metrology is concerned with the measurements that influence economic transactions; legal metrology is a very refined type of metrology. This field does not use physical tools as the other fields of metrology use. Instead legal metrology focuses on the buying and selling of materials for economic studies. Also, legal metrology can also be used for law enforcement fields.

Scientific Metrology deals with the organization and development of measurement standards, and their maintenance. It is deeply involved with new research and new technologies for industries concerning government, healthcare, and research for commercial products.

Industrial Metrology’s purpose is to ensure that instruments that are widely used in a variety of industries are all functioning properly. One example where industrial metrology is seen is in the manufacturing of products for the commercial industry, the testing of aircraft, the functioning of large machinery, or even in factories using rotating equipment during the manufacturing of their products.

Metrology has been applied to 3D measurement in order to measure size, volume, and depth. It is crucial to know the exact size of an object when working with it for a variety of reasons. The ability to collect measurement data is a key part of 3D Metrology. This helps in the manufacture of manufactured products.

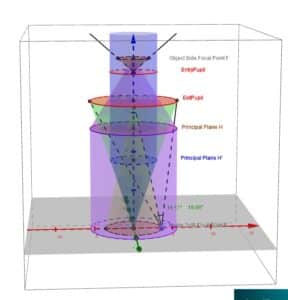

CMM technology is used to perform 3D metrology. Other tools that are commonly used include machine vision systems and hand tools. CMM refers to coordinate measurement machines. CMMs are typically performed with a non-contact sensor, a scanning contact probe or a touch probe. Machine vision (MV), is a technology and method that provides imaging-based automated inspection and analysis, typically for industrial applications.

In the field of 3D Metrology, accuracy and precision are paramount. Accurate data in 3D models will lead to greater repeatability and a future of automation.

The cameras and lenses in the cameras must be able to produce the sharpest image possible. We stock a variety of precision optics that can be used for 3D metrology. Our design team will work with our manufacturing facility to engineer and produce a lens that meets your specifications if we do not carry the exact product you need.

Related Posts

Trends In Remote Security Monitoring

How useful was this post? Click on a star to rate it! Submit Rating As you found this post useful......

Capturing The Details: The Leading Megapixel Lens Manufacturers Redefining Clarity

How useful was this post? Click on a star to rate it! Submit Rating As you found this post useful......