3D Scanning

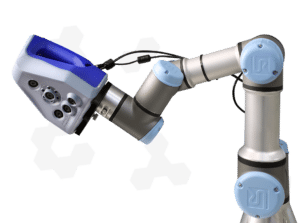

3D scanning involves capturing data from the real world and converting it to a 3D version. 3D scanners have been used primarily for industrial purposes until recently. 3D printing, particularly for hobbyists and professionals, is on the rise. The demand for 3D scanners that can turn real objects into 3D printable model is also growing.

A 3D scanner analyzes data and captures geometry and colors from a physical object in order to convert them into 3D digital renderings. The scanning process gathers points from the object’s surface and generates the geometric shape by extrapolation. Each 3D scanning technology has its own limitations, advantages and costs.

Combining 3D scanning with printing can be beneficial for all phases of the product design process, from concept to manufacturing. This will reduce the time and number of design revisions, thereby lowering the cost of each prototype.

We will design and manufacture your precision lenses in conjunction with your 3D scanner team.

There are two main categories of 3D scanners, which each cater to different applications and scanner types.

Scan for Color

You can scan a part to digitalize its colors and shape for educational or medical purposes. Then, print the object using a 3D color printer. The final product will be the exact same color and geometry as the original and allow you to print more copies.

Scan for Inspection

You can scan parts to inspect them for defects or compare the printing results against the original CAD files. You will need to scan the object at high resolution in either case.

LiDAR, a laser tool similar to RADAR, can be used by scanners to map the inside of pipes, mineshafts, and caverns. They can even scan large construction sites. These systems are used in mining to calculate ore extraction, or for surveying to create digital maps of terrain.

It is not possible to model internal structures using optical scanning. Instead, CT scans or ultrasound images can be used. Researchers have recently created the first full-skeleton model of a live animal using the CT scan data.

The same data is used to reconstruct facial features from mummified remains found in Egypt and the newly discovered remains King Richard III. Researchers at the University of Dundee used CT scans to create a solid version of King Richard III’s head.

Almost anything can be reproduced using 3D printing and scanning technology, as long as there is an existing 3D image. A 3D scanner and the right printer can reproduce any object at any size, from a skyscraper down to an earring.

SUPERIOR® Optics is proud to have developed a precision lens specifically designed for 3D printing and scanning technology that you manufacture. Our skills and expertise can be put to work for your benefit.