When Developing Your Vision System? 5 Ways Your Vision System Building Partner

You’re faced with an immediate dilemma when you need to develop or source a new vision systems: should you buy a product off the shelf that can perform well for your application or build your own from scratch? In our whitepaper, To Build Or to Buy – A Vision System Builders Dilemma, we’ve discussed some of the technical issues surrounding that question.

5 Ways Your Vision System Building Partner Can Support You

To develop a vision system, you will need experienced hardware engineers and software developers with experience in data communication protocols and device driver development. You also require access to opticians, experts in image data encoding and image tuning.

You may be forced to create your own vision system if you cannot find a suitable off-the shelf solution. There are ways to reduce your risk and speed up your time to market by using a function product.

Distributors and suppliers can help you to determine the best sensor technology and optics combination for your application. By purchasing common modular components, such as sensor modules and optical modules, you can reduce the cost of design and engineering.

One way to minimize risks is to look for industry partners to help support you when developing your vision system. Here are 5 ways your building partner should be able to provide:

Selecting the right image sensor

Image sensors are at the core of vision systems and determine many other design decisions, such as the choice of optics, the data transport protocol and the module design. The choice of sensor can be straightforward in some cases. If you need a low-cost, color image sensor, then you can choose from a variety of rolling shutter sensors depending on the sensitivity and resolution you require.

This decision is more complicated if you need to capture high-speed movement or use 3D sensing. Many functional questions need to be addressed. A global shutter sensor may provide the performance required for high-speed applications. However, it could be problematic in terms of lighting requirements and data rates. You might decide to use an event-based or combination of sensors in your solution.

There are many technologies that can be used for 3D depth sensors. Each has its own advantages and disadvantages. Indirect Time-of-Flight sensors, for example, provide excellent performance over a wide range working distances. However, they also present engineering challenges and functional limitations, such as sensitivity to ambient lighting.

Designing the optics for your vision system

Your choice of image sensors and your operating range and lighting requirements will influence your lens choice and mount.

If you have a fixed range and need a small sensor, an M-12 screw mount lens may be the best choice. However, if your system needs a large sensor with a large circle of vision, then you will likely need to use a C/CS lens. You may choose a manual aperture lens based on your operating range and the lighting conditions.

For some sensor technologies (such as SWIR sensors), specialized lenses made from Germanium or other substrates are required. You may need lenses with large apertures for low-light applications.

5 Ways Your Vision System Building Partner Can Support You

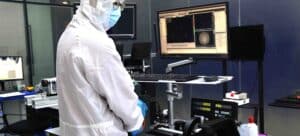

For optimal results, some aspects of the development of vision systems require access to an optical laboratory. It is rare that a combination of optics and sensor will produce an ideal image straight out of the package. Instead, it will need calibration and the creation of a “tuned image profile” to achieve optimal color reproduction and image quality.

Our optics lab offers a wide range of services including optical alignment, EMVA1288 testing and image tuning.

Our “ecosystem”, which combines hardware modules, device driver software, and optimized image profiles, gives developers of vision systems a head start when creating new products.

Offering off-the-shelf modules

5 Ways Your Vision System Building Partner Can Support You

You don’t have to reinvent the wheel just because you are developing your own system. SUPERIOR® Optics is one of several distributors that manufactures and sells standard modules. These include sensor modules which provide connectivity for a specific image sensor and a standardized interface, as well as sensor adapter module which provides an onboard clock, as well interfaces for a number of data transport protocols including MIPI and CSI-2 MIPI.

Some imaging companies manufacture optical modules that are matched combinations between a sensor, a sensor module, a lens mount and corresponding lens. These components are found in every vision system and can be easily “plugged in” based on your requirements.

SUPERIOR® Optics offers a variety of optical modules, many of which are based on combinations of optics and sensors that are most commonly requested.

If your project requires a unique optical module that is not available, you can reduce the burden of engineering and development by using other modular components in a vision system.

Your partner in the development of your vision system should be able work with you on identifying design requirements for your system that could be met by an off-the shelf module.

Providing developer kits

You need to have a good starting place for prototyping, even if the end goal is custom hardware for your image processing component.

Depending on the final product, you can choose to prototype the vision system with a small-board computer such as the Raspberry Pi or an embedded computer such as the NVIDIA Jetson products. You can also use a Field Programmable Gate Array FPGA like the Xilinx Kintex.

The majority of imaging companies offer a version of a development kit that is compatible with these options. These kits can save engineers time by providing them with basic hardware and software tools to transfer image data from the camera into an embedded computer or FPGA.

We offer a variety of image processing adapter modules that facilitate communication between sensor modules and image processor solutions. We also offer developer kits and carrier board for some of our most popular prototyping tools, such as NVIDIA Jetson embedded computer.

A developer kit allows your team to quickly get up and running with the core technology, so that they can concentrate on software development and feature development.

Custom vision solutions and manufacturing services

It may not be possible or cost-effective to manufacture all the optical and electronic components of your system, even if you have your own manufacturing facility. Working with a partner to build your vision system allows you to leverage their manufacturing and engineering facilities.

A good partner can help you better align your requirements by working with you on defining the size and function of your needs.

You should work with a partner who can design a vision system that meets your needs, whether it’s thermal control, ergonomics or EMC requirements.

The custom solutions team can assist you in designing and developing custom hardware modules and image components if you have specific design requirements for the vision system that you are developing.

We offer a range of manufacturing services, including the development of custom components for vision systems as well as optical alignment and final assembly.

Conclusion

The choice to build your own vision system can be daunting, and it comes with risks that can be discouraging to your engineering team – especially if this is the first vision system your company is considering developing. However, it can also reward you with a significant competitive and technology advantage over your competitors, which is why the question of “to build or to buy” is worth considering in the first place.

If your company is developing a vision system, finding a vision system building partner can be a good first step toward your goal. We can help – just as we’ve helped dozens of other companies to develop scores of innovative new vision systems. We can help you to identify risks and minimize your exposure to them, and we can help fill in the gaps where your engineering and manufacturing teams need support.

Consider making SUPERIOR® Optics your vision system building partner.

Related Posts

Choose One of the Best CCTV Lens Manufacturers

Table of Contents Sr# Headings 1 Introduction to CCTV Lenses 2 Why the Lens Matters in CCTV Systems...