A scanning system moves a laser in two or three dimensions linearly, usually by using scan mirrors or galvanometers. The laser beam can be focused to engrave images on different materials and for drilling, cutting, or other applications. When using traditional lenses for this application, however, the profile changes as the focus beam moves away. This is because the lenses are focusing light onto a curved plane (which is also one of many aberrations, such as field curvature). The focus of the beam can change the optical power at the surface of the material, causing manufacturing errors.

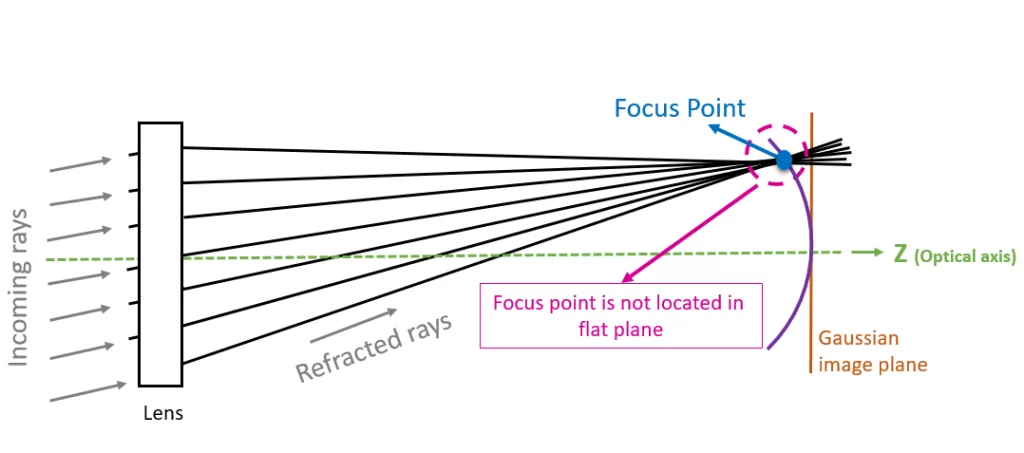

A regular lens’ focal point is a plane that has a curvature.

This problem can be solved by using “flat-field” scanner lenses, which focus light on a flat surface at the focal point. Traditional flat-field scanning lenses, however, create an image proportional to both the focal point of the lens and the tangent of the scanning angle. The image will not change linearly as the scanning angles changes. This can cause manufacturing mistakes.

This flat field can be created by F-theta lens. They are used for a variety of applications, including laser welding and laser engraving, laser drilling, LIDAR and scanning laser microscopy.

These lenses are known as f-theta because they create an image that is proportional to both the focal length of the lens and the scanning angle Theta.

Difference in the focal plane for a convention lens, flat field scanning lens, and f-theta lens (image source Thor Labs)

There are different ways to decide what kind of f-theta lens is the right one for you. Things to keep in mind are:

-

Wavelength of operation. Are you working at a single wavelength? If so, are you in the visible, IR, or UV ranges?

-

Spot size. This may be critical if you are in manufacturing.

-

Scanning area. Sometimes referred to as Scan Field Diameter (SFD). It is a diagonal on the image plane where the beam can be focused.

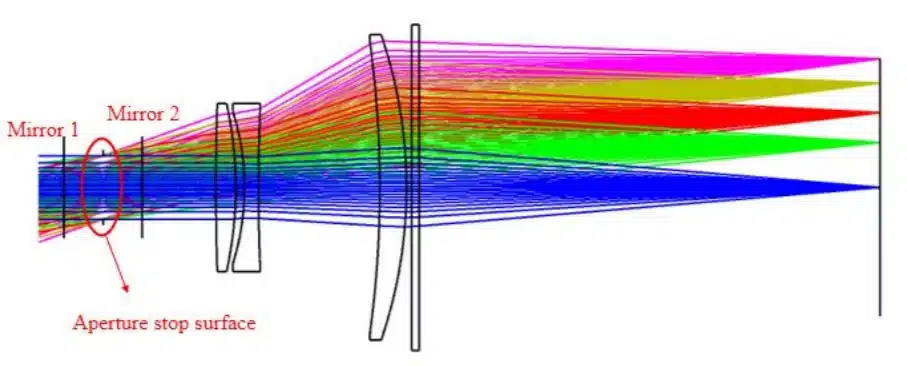

A telecentric lens or a non-telecentric one is another parameter you should consider. In a telecentric system, the rays in the image plane run parallel to the optical direction. The beam will not shift laterally when the object is moved away from the focal point. If you’re working with an engraving machine but you can’t guarantee the distance from the plate to be engraved to the f-theta, you might need a telecentric to ensure that the image will not be distorted.

Example of a telecentric f-theta lens

Example of a telecentric f-theta lens

(Please see this article for a detailed explanation of wide angle lens types including about f-theta lenses)

#lens design, #lens design consulting, #machine vision

Related Posts

The Future of Driving Monitoring: Advancements in Vision Technology and Lenses

How useful was this post? Click on a star to rate it! Submit Rating As you found this post useful......

Backup Camera System

How useful was this post? Click on a star to rate it! Submit Rating As you found this post useful......