When Build or buy a vision system? Key factors to decide with a dilemma:

Should they buy an existing off-the-shelf solution, or develop their own?

It is undeniable that developing your own technology has many advantages. You control the features, you own the IP and you have control over the lifecycle of the product. If you are in an industry that is utilizing computer vision, it could give your product a competitive edge.

Build or buy a vision system? Key factors to decide

Off-the-shelf products may not be able to provide the features or functionality that you need for certain applications. If this is the case, it makes sense to invest in developing your own vision system.

There is a risk involved in developing your technology. It is unlikely that the engineering team of your company would have a complete understanding of every aspect of your project if you are not already working on vision systems. A vision system is developed by experienced hardware engineers and software developers with experience in data communication protocols and device driver development. They also require people who have a basic understanding of optics, color, image data encoding and image tuning.

The total cost of ownership of this technology includes the costs of recruiting and attracting the required engineering talent.

It can be difficult to navigate the supply chain of imaging and optical components. It’s a relatively small industry. The majority of optics manufacturers are in east Asia. This can lead to supply chain delays and interruptions depending on the location where your components were sourced.

The good news is that you don’t have to go it alone for every part of the technology stack. Imaging companies like SUPERIOR® Optics can supply modules for key components of a vision system, device drivers, and technical services and support for specialized tasks including optical alignment, and the development of tuned image profiles for your choice of optics, sensor, and application.

KEY COMPONENTS OF A COMPUTER VISION SYSTEM

Image sensors are the core of every vision system. The application you intend to use will dictate the type of sensor that you choose. This sensor will also determine the rest of your technology stack including optics, data interfaces and the image processing component. In order to select an image sensor, you must first develop a set specifications.

The Image Sensor

- Do you require a 2D image, or a 3D depth sensing technology?

- What is the required operating spectrum of the sensor? Is this for visible light, or short-wave infrared? Will your vision system be operating under controlled conditions or outside? Will your vision system be required to operate in low light conditions?

- What is the desired resolution of the acquired image or video?

- What is the required image acquisition speed and frame rate?

- Will your application require a global shutter, to capture high-speed motion, or will a rolling shutter sensor be adequate?

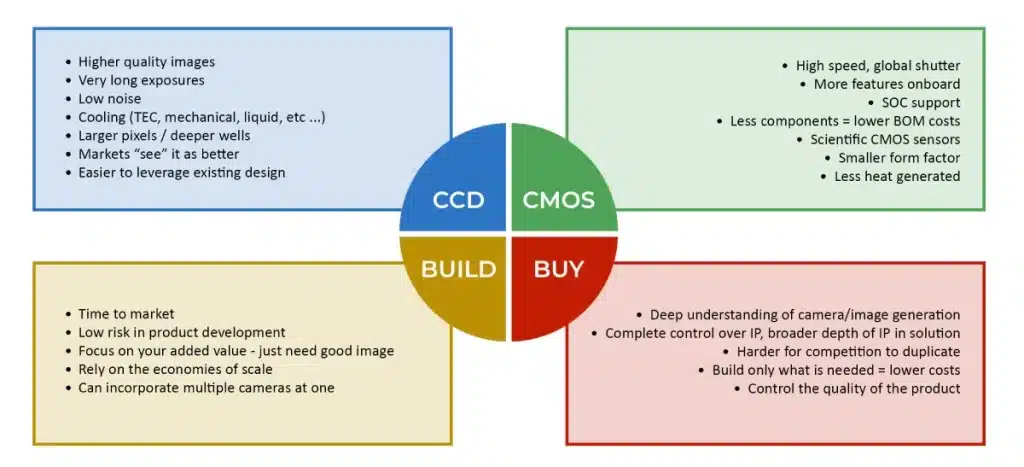

- Is a charge-coupled device (CCD) the best technology for your application, or would a complementary metal–oxide–semiconductor (CMOS) sensor be more appropriate?

The issue of CCD sensors versus CMOS can be complex. Until recently, CCD sensor offered advantages that CMOS sensors did not. However, this has changed and CCD sensors have been phased out. The white paper “To build or to buy?” discusses this issue in great detail. You can find it here.

Build or buy a vision system? Key factors to decide

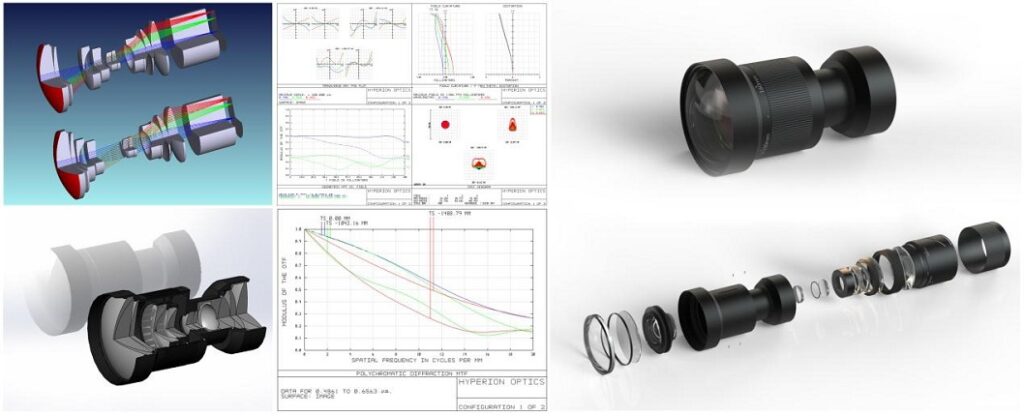

Optics

The vision system you choose must support the entire range of focal lengths, lighting conditions and fields of view needed for your intended application.

Optics for your vision system are largely determined by the following: the size of your sensor, the operating requirements of the image circle and the range of operation of the system. For smaller image sensors or applications that require the lens to adapt its focus and iris settings, C/CS mount lenses may be better.

Your choice of optics will be dictated by certain specialized applications. If you use a SWIR sensor (short-wave infrared), you will be limited to using optics that are designed for infrared spectrum (normal glass elements absorb the infrared). In some machine vision applications, you may need to determine with precision the alignment of objects that your vision system observes. You may be required to use a Telecentric Lens to create an image in orthographic projection.

You will need to determine the optical requirements of your vision system. This includes selecting and designing a suitable lens mount, and ensuring that the components are aligned correctly during manufacturing.

Sensor Module

Sensor modules are the core of all optical modules. The sensor module is not only a substrate, but also a lens mount and an adapter to connect the sensor data lines to your vision system. It must be able to provide physical access to these data lines and the appropriate sensor adapter to use for the data communication protocol used in the vision system. This component is expensive to design from scratch because of the density of data lines that connect to the sensor and the need for a multilayer PCB.

The majority of image sensor companies and distributors offer a wide range of sensor modules to suit different sensor types and communication protocols. Even if you decide to design and construct your own vision system, you may find it more cost-effective to purchase an off-the shelf sensor module.

Data Communications Protocol

MIPI and MIPI Cameral Serial Interface 2 and 3 are the most common communications protocols used in vision systems. MIPI is an extremely fast serial protocol that can be used with short ribbon connectors. However, it requires all of your optical components (image sensor, processor, etc.) to be in the same enclosure.

CSI-2, CSI-3 and MIPI are the latest extensions to the MIPI standard that relate specifically to imaging. These standards are faster and more efficient than other serial protocols, like USB-3. They also support multiple channels and are relatively cheap to implement.

The gigabit multi-serial link protocol (GMSL), which allows for the transfer of high-speed raw image data across relatively long distances using an inexpensive coaxial cord, is commonly used in applications such as the automotive industry or robotics. This protocol is used almost exclusively for robots and automotive back-up camera systems.

Sony’s SLVS (scalable low voltage signaling [with] integrated clock) is a new standard for high-resolution image sensors. This protocol is the ideal choice for vision systems that require extremely fast data transfers.

The choice of protocol for data communication will influence the engineering decisions made for all components between the sensor module to the image processor. Your choice of protocol can influence everything, from the drivers you use to the connectors mounted on your PCB.

Look for modules that support the communication protocol you choose if you are building your own vision system.

Image Processor Adapter

You can choose to transfer the raw image data from the sensor module directly to the image processor if you are building embedded image processing hardware.

If you decide to build a system using a small-board computer, such as the Raspberry Pi or embedded computers, like the NVIDIA jetson series, then an image processor is a valuable component.

Image Processing Adapters offer a wide range of inputs to support different data communication protocols including MIPI and CSI-2. They also provide SLVSEC. They are designed to communicate with a particular platform, such as an embedded computer, like the NVIDIA Orrin or a Field-Programmable Gate Array (FPGA), like the Xilinx Kintex.

Image Processor

A vision system would not be complete without an image processor. Image processors take the raw data of the image sensor and decode it. They then process the data into color channel data. Finally, they construct the final image which may be further encoded as part a video datastream. Image processing will usually apply a profile for image tuning to raw image data to correct brightness and color. This is done to compensate for sensor, optics and lighting in the vision system.

Your engineers will not immediately begin designing circuit boards, even if the ultimate goal is to create your own embedded image processor hardware. As a starting point, you can use a variety of development kits and research and development platforms available from image component suppliers and imaging companies.

CONCLUSION – TO BUILD OR BUY A VISION SYSTEM

Intellectual property and competition are always linked. It might make sense, therefore, to build your own custom-made vision system.

Your own design may be the best option for your application. You can gain competitive advantage by building your own vision systems. If you can implement that design in such a way as to make it difficult for your competitors to manufacture, or cheaper than any other off-the shelf solution they might offer. You win if you can make your competitors always try to catch up.

To build your own vision system, you need to think long term. Your project’s timeline must begin with the recruitment of engineers to create the system and continue throughout the lifetime of the product. You must not only create a product but also support it and plan for the future of your vision system.

It’s not necessary for you to assume all of the risk. You can use the support of imaging companies and suppliers in order to design and implement your vision system. By purchasing common components like optical or sensor modules, you can reduce the cost of engineering.

Third-party services, such as optical alignment, can be used to reduce costs in plants where a direct investment may not make sense. You can also use contracted expertise to provide services such as image tuning, which are more or less a one-off service for each new product.

It can be a daunting and risky decision to build your vision system. You can gain a competitive edge and technological advantage over your competitors.

What to look out for when choosing a partner for the creation of your Vision System of SUPERIOR® Optics.