Why is a Machine Vision Lens the Best in the Market and What Makes It Unique?

Our high-performance Machine Vision Lens have a large selection of focal lengths, allowing you to choose the perfect factory automation lens for your application, whether it’s inspection, measurement, sorting, or other machine vision tasks.

The machine vision lenses are designed and engineered to meet the needs of modern industrial imaging systems.

What Are the Industries Where the Machine Vision Telecentric Lens Used?

Machine Vision Telecentric Lens are mostly used to view objects in imaging systems. They are imaging parts that focus on an image of an analyzed object on a camera sensor.

However, it depends on the lens. A Machine Vision Lens is used to remove perspective errors. It offers the best adjustable magnifications and focal lengths.

Machine Vision Lenses also help the user illustrate the characteristics of an object by using certain angles and techniques.

Advantages of a Machine Vision Lens

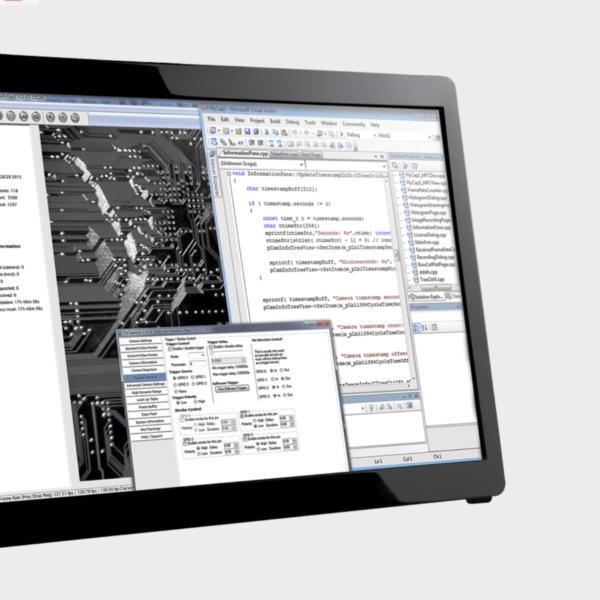

- Machine vision lens are a product of high-end technology and optical design expertise. Superior has put all its expertise into ensuring accurate imaging performance. It also focuses on assembly and inspection procedures on manufacturing lines.

- Machine Vision Lenses and FA Lenses offered by SUPERIOR perform well not only with legacy line sensor cameras but also with emerging large format area sensor cameras.

- Fixed focal length lenses are commonly known as factory automation lenses (FA). Apart from the FA, machine vision is also capable of C-mount lenses or prime lenses. They are imaging lenses made with a singular angular field of view and a constant focal length.

- Fixed focal length lenses are limited in their working distance.

What Are the Other Varieties of Machine Vision Lenses?

These lenses are available with a variety of mounts, anti-reflection (AR) coatings, resolution options, and much more.

Apart from Machine Vision Lens, we have others as well, and they are:

- Telecentric Lenses

- IR Imaging Lenses

- Large Format Lenses

- Line Scan Lenses

- UV Lenses

- Variable Focal Length Lenses.

We have different resolution levels such as 12 MP, 8 MP, 5 MP, 3 MP, and VGA. Our Machine Vision Lenses offer a great line of high-performance lenses with many focal lengths and sensors.

Applications include image capture, barcode scanning, night vision systems, medical systems, high-speed imaging, and machine and robotic vision systems.

Why Should You Use a Machine Vision Telecentric Lens?

Machine Vision Telecentric Lens has the great ability to perform quickly. It is repeatable, with high accuracy and great performance. If you wish to achieve the best and highest accuracy in your work, get our telecentric lens.

It helps you be unique and capture photographs with accuracy using the characteristics of telecentric lenses to see the impact and performance.

So, what are you waiting for? Contact Superior Optics today to buy the best Machine Vision Lens and make your journey as a creator successful.

Visit our website today and order the lens to improve your skills. You can even book our lenses to improve your security so that you can enjoy quality time with them.