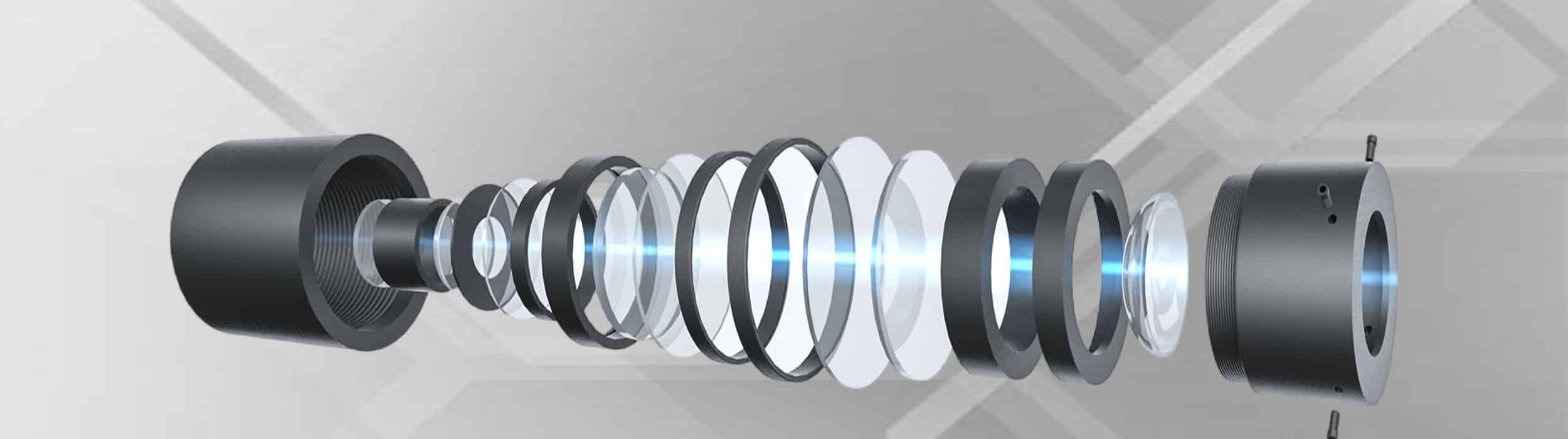

SUPERIOR® Optics uses its over 20-year experience in design, manufacturing and metrology to offer our customers world class services for lens manufacturing and design. Our engineering team is capable of providing various types of lenses design and assembly. This includes all aspects of illumination and imaging design from LED to gas-discharge lamp illumination systems design as well as the design for the overall opto instrument components and customized optical module.

SUPERIOR® Optics can customize from deep ultraviolet to the far infrared photography, microscopy, metrology, monitoring, and other customized projection lens design and concept evaluation.

From design concepts and individual component preparation to entire module/assembly, SUPERIOR® Optics’s engineers provide our customers with world class engineering services that are second to none.

SUPERIOR® Optics’s global team can bring your vision to reality with its custom lens design solutions in prototyping and volume production.