Optical coating with a thin-film is used to improve transmission, alter reflective properties or change the polarization (direction) of light that passes through an optical component. An optical coating may be a simple layer of metal such as aluminum, or it may be a complex dielectric coating formed of multiple thin layers of material, where the composition, thickness, and number of layers is carefully controlled for a precise result.

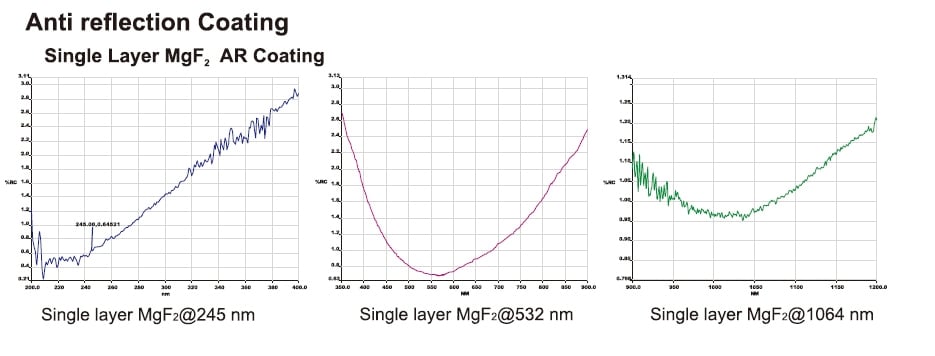

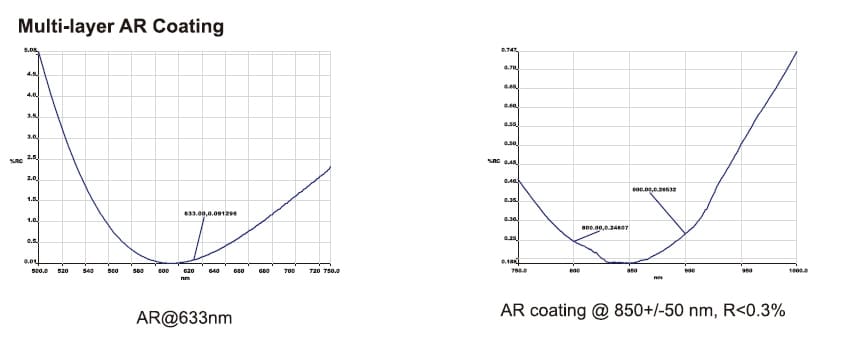

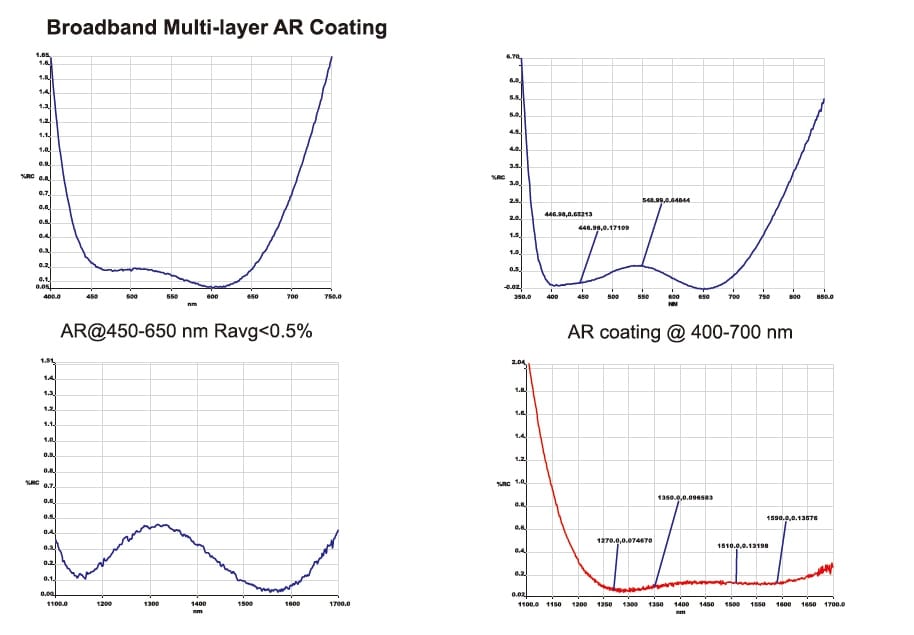

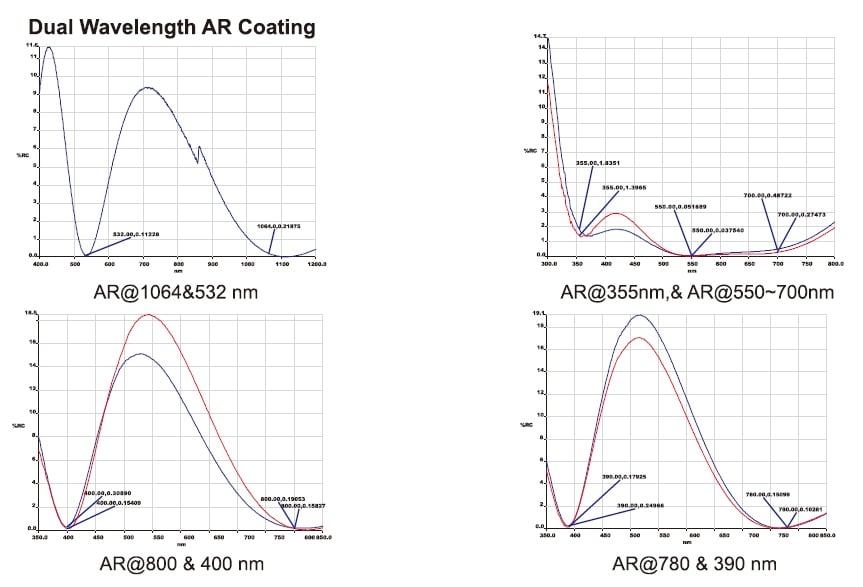

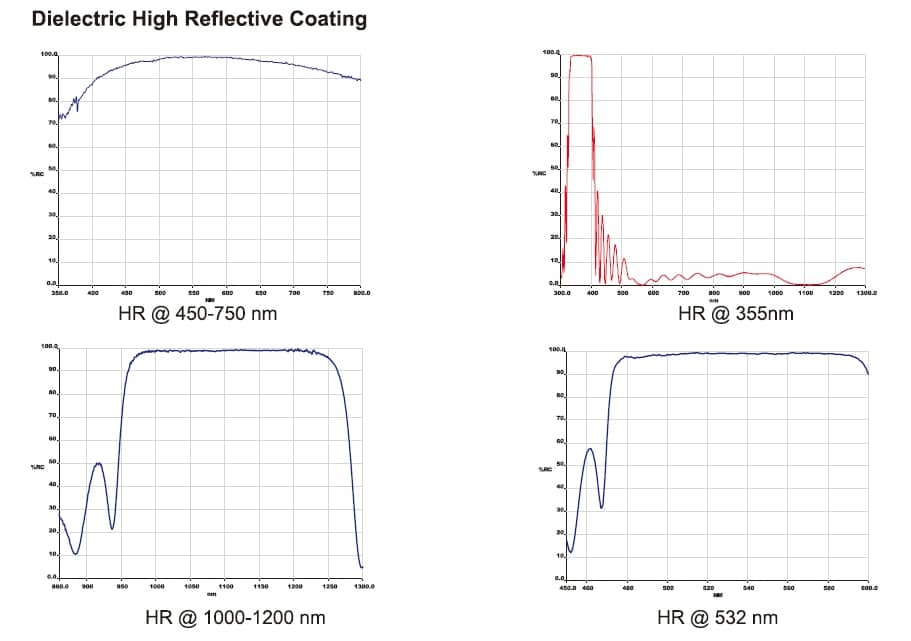

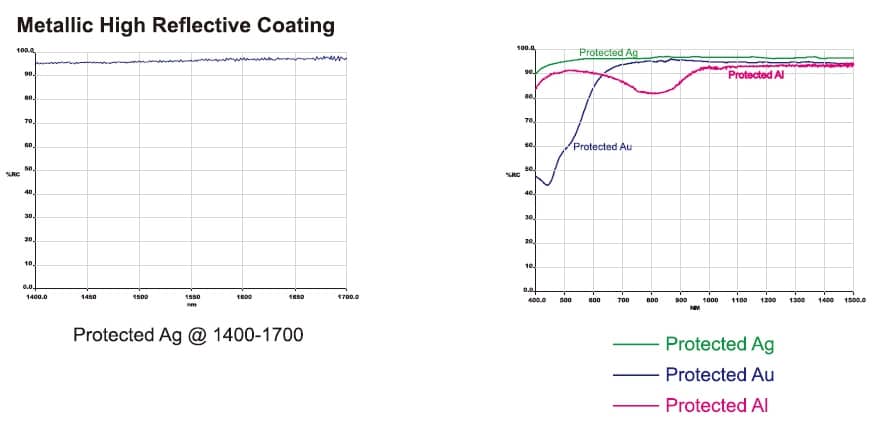

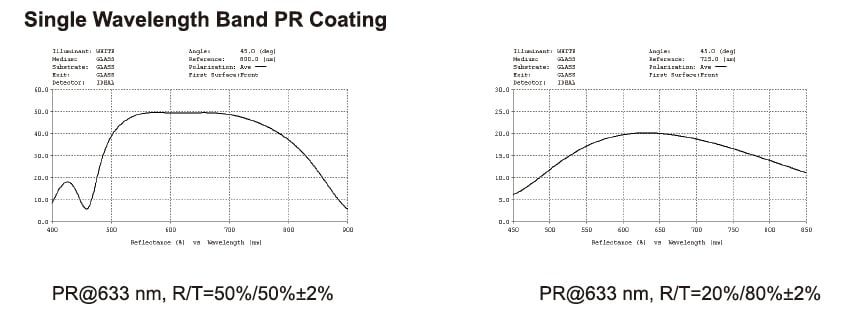

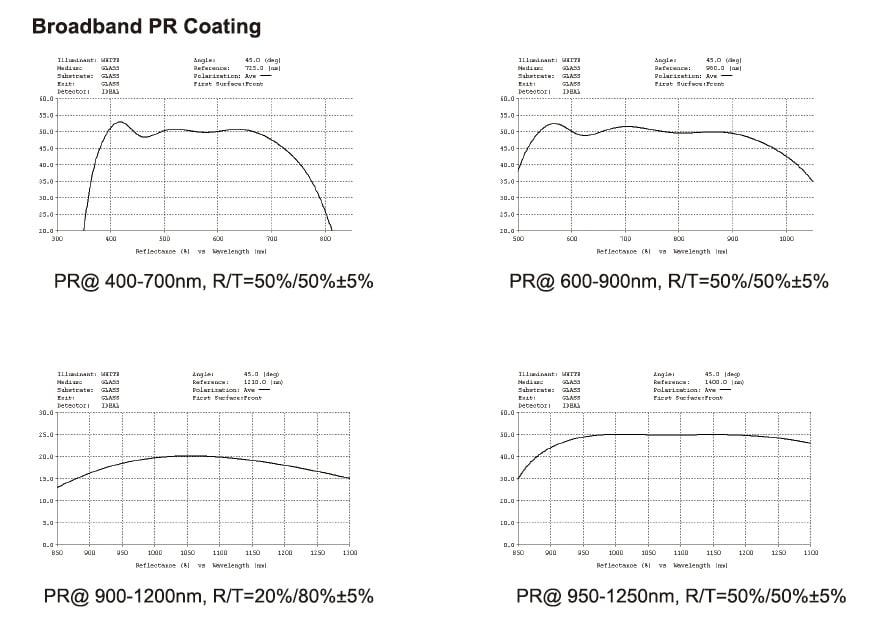

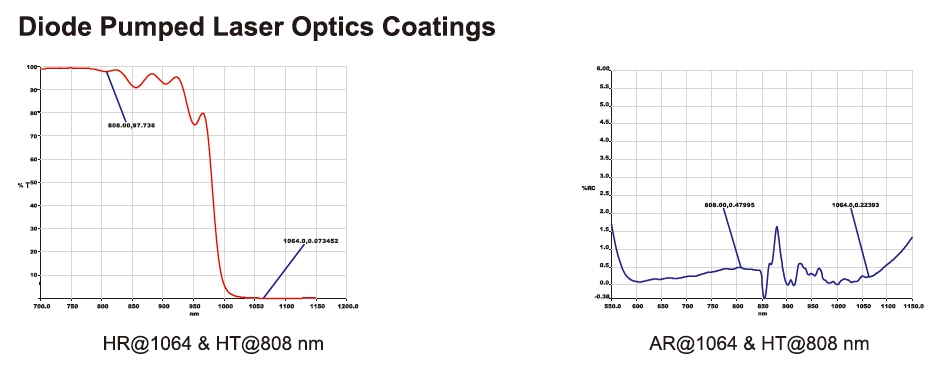

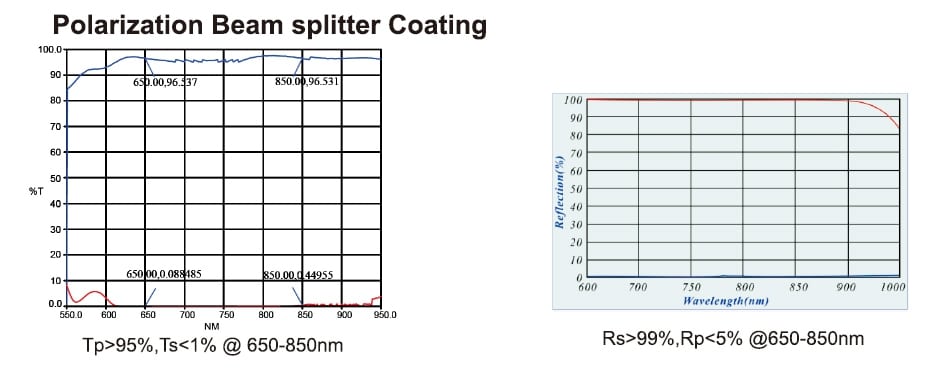

The Coating on the optical element is very important, which can improve the transmission, high reflection, etc. SUPERIOR® Optics offers all kinds of anti-reflective (AR coating), high reflective (HR Coating) and partial reflective (PR Coating) coating according to customer’s requirement. We can produce a wide variety of coatings from simple single layer AR coatings using MgF2 and mirror coatings to complex multi-layer dielectric coating. Typical types of dielectric coatings are BBAR, V-coatings, and Dual wavelength coatings.

SUPERIOR® Optics measure the coating spectral curves by Perkin-Elmer Lambda 900(UV/VIS/NIR) spectrophotometer for our coatings. The coating spectral curves measured by Perkin-Elmer Lambda 900 can be provided upon your request. We make coatings meet the Standard Mil Spec tests of Abrasion (Mil-C-675A), Adhesion (Mil-M-13508C), Hardness(MIL-M-13508C).