The success of devices, platforms, and instruments that rely on imaging and optics is dependent on reducing the lifecycles of custom optical products and delivering Rapid Optical Prototype. The introduction of new technologies is so rapid that it has become necessary to reduce the time required to create prototypes. The quicker customers prototype, the sooner a product will reach market. SUPERIOR® Optics has different resources and solutions to create and optimize rapid optical prototypes for customers based on their timeline and requirements.

Rapid Optical Prototype Solutions

LRIP Rapid Optical Prototype

SUPERIOR® Optics has leading advantages in Rapid Optical Prototype services for LRIP (Low-Rate Initial Production) and Proof-of-Concept projects.

- Various fast material accesses, such as Schott, Ohara and CDGM. We also offer mold pressed substrates for prototyping at competitive pricing

- More than 6,000+ test plate, which can dramatically shorten the overall lead time to delivery

- Specialized prototyping production team to oversee project from procurement to delivery

- Excellent internal resources aiming at 4-week delivery from grinding, polishing, to coating

- Free initial prototype design consultation

Please contact us before finalizing any optical design. Before production, our dedicated prototype team will check the availability of materials, lead times, optimal substrate selection, and fabrication tolerance definition. We will always try to make the most practical suggestions to avoid any unnecessary delays.

Fast Molded Substrates

1. Pre-Annealed Glass Sheet

2. Pressing

3. Fine Annealing

4. Production

30 pcs Pressed Substrates

1. Glass Strip

2. Pre-Slice Actual Usage

3. Slice

Raw Material Preparation Pressing vs. Slicing (Prototyping Qty)

Sometimes, optical designers will face prototyping issues when there are more than five different spherical glass elements in a design for a lens set of 5-10 lenses. The project is often faced with budget constraints due to the limited availability of materials in the correct blank sizes.

Unlike most Chinese vendors, SUPERIOR® Optics has access to Schott & Ohara glasses. You can check out our glass inventory. All listed glasses are also in pre-annealed sheets. The pressed substrates have a precision refractive indices tolerance of +/-0.00002 after fine-annealing.

Our engineers perform cost analyses for any project size and determine whether manufacturing glass strips or molded substrates is the most cost effective approach. Our domestic glass molders provide us with low-MOQ molding services and the most reliable annealing technologies. We can help you make the most of your project budget by using our Rapid Optical Prototype services.

Flexible Manufacturing Planning

SUPERIOR® Optics has advanced manufacturing technologies and devices, giving us a unique advantage in LRIP projects.

1. Exhaustive Test Plates Inventory. We stores over 6,000+ test plates. If our stock radius data matches the design of your test plate, then there is no additional cost for the test plate and the relative lead-time can be reduced.

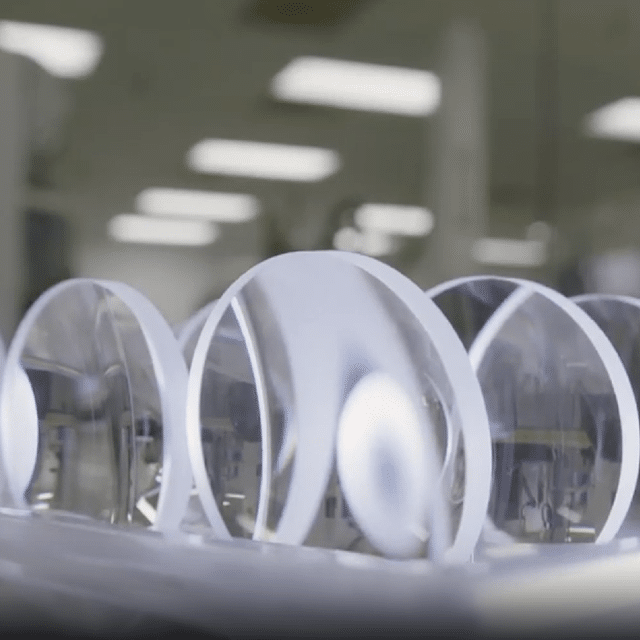

2. High Surface Accuracy by Conventional Processing. Our polishing operators have nearly 20 years of optics fabrication experience; we regularly deliver high-precision elements with 1/8-1/10 lambda surface flatness.

3. SPDT Aspherical Capability. Our aspherical machining and polishing techniques ensure that you don’t need to procure aspherical parts elsewhere.

4. Quick and Convenient Coating Bundle. For common coating specs in the Visible wavelength range, LRIP projects can be arranged along with our regular daily coating operation and reduces the overall coating cost.

Talk to our sales engineers about how SUPERIOR® Optics could make your purchasing easier and quicker. About our production capabilities, Read More : Opto-Mechanical Design + Lens Assembly.

Related Optical Design

Key Details

Project Date: 24.02.2015

Project Budget: 10.000 USD

Technologies: PHP, HTML, CSS, JS

Conventional Technology

Ultraprecision Machining

Coating Arrangement

Lens Assembly

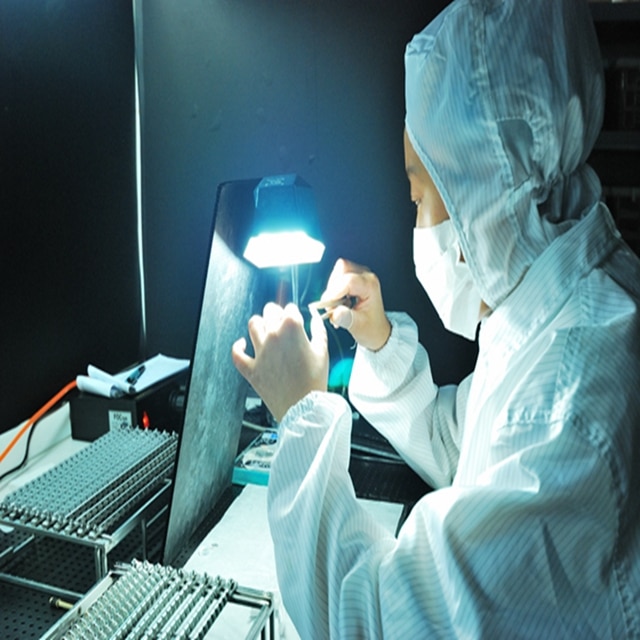

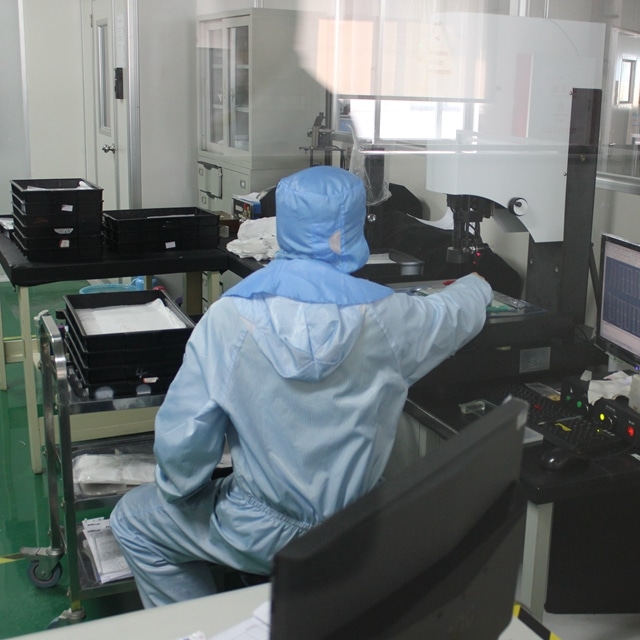

Optical Metrology

At SUPERIOR® Optics, as In Precision Optical Systems, The Leading Advantages in Rapid Optical Prototype

Frequently Asked Questions

1. What are some optical considerations for camera module design?

f-number, object distance, fixed focus/autofocus, field of view (FOV), operating wavelength band, frequency range, MTF, scene dynamic range, distortion, chief ray angle (CRA), stray light requirements, and centration tolerances.

In camera module manufacturing, VI and DFM offer advantages such as intricate manufacturing (for complexly interrelating parts), rapid prototyping, scalability, and, most importantly, a path to continually reduced size, weight, power, and cost (SWaP-C).

3. What are the components of the optical assembly in camera module manufacturing?

Axial alignment, precise optical pathway placement, centration, electro-optics integration, optical bonding, and sonic welding techniques